Every brilliant, world-changing object or product all went through the same process. It all began as a bright spark in someone’s mind, and found its way onto paper in a sketch. From there it existed as prototype. It was tested and prodded and experimented on to make sure it was perfect. The prototype stage is one of the most important aspects of product development. If you’ve got a brilliant idea, this post will help you turn it into a functioning prototype, ready for production.

Research and Drawing

Before you rush into building your first prototype, take the time to research and develop your idea. Focus your thoughts on the target market and the potential customers. Who would buy and use this product? Start to tailor it specifically for them, and hone the concept. Look for similar products in the market. Take inspiration, but make sure it’s unique. Spend some time drawing and sketching the early designs until you’re happy.

Make it by Hand First

The first thing to understand about prototyping is that it can be expensive. The materials and machinery involved can cost a lot of money. You’ll want to keep your startup costs low initially. That’s why so many inventors build the first prototype by hand. They’ll use anything they can find lying around the house or workshop. It doesn’t have to be fully functional yet. It will just give you a sense of dimension, form and concept.

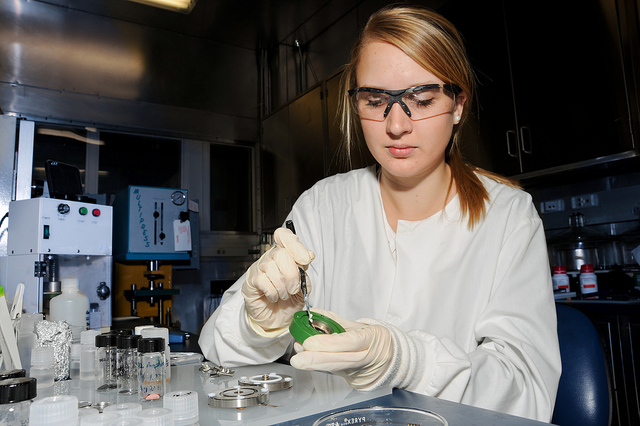

Pre-production Prototype

Now’s the time to start working towards the fully functional prototype. By this point, you should have ironed out any immediate flaws and perfected things for your target market. This stage is expensive and you want to come as far as possible before you start. It’s time to get machinery and real materials involved. Some entrepreneurs will use third party companies to build the parts they need, or the entire prototype itself. For example, you might use cardboard cores manufacturers or metal workers to construct parts. Others prefer to keep things in house by using a 3D printer or other tools.

Test Functionality

Congratulations! You’ve now got your first working prototype. The first thing to do is test its functionality. After all, that’s the core aspect of the product. Does it work like you’d hoped? What could be tweaked to make it better? This is the phase where any unexpected problems will show up.

Test the Materials

It’s also the stage where you will discover if your materials are right for the job. They could be perfect on paper, but in situ, they might not handle the pressure. You might have used plastic, where metal would be more appropriate, for example. Analyse each material separately and make any alterations.

Get Feedback

Now that you’ve got a working model, you should get trusted, honest feedback. The best test is often asking your family to use the prototype. Is it simple and intuitive enough for them to use it? After that, take it to trusted industry experts and get professional feedback.

After all this, it’s probably back to the drawing board to make some final changes! Don’t worry, every designer and inventor has been through this! The more work you do here, the better your final product will be. Best of luck!