When your hot new product is still just an idea rattling around in your head, it can difficult to visualize how the finished product will look.

This can make it difficult for both your clients and staff to know exactly what it is that’s being worked towards.

While advancements in technology now allow us to make extremely detailed digital 3D models, an actual physical prototype is preferred.

Advances in 3D printing technology have led to the rise of companies such as Prototype Projects who specialist in ‘rapid prototyping’.

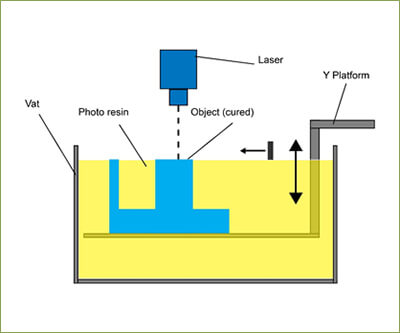

For a brief overview of what 3D printing is and how it works, check out this article from 3Dprinting.

We’ve taken a look at some of the advantages that using rapid prototyping can bring to product development.

Brings a Concept to Life

The most obvious benefit of prototyping is that it takes your idea from the computer screen and actually makes it tangible.

The problem with CAD assisted prototypes is that they don’t really prove anything, whereas an actual physical prototype allows you to see and feel the product.

This is especially useful when working for a client who wants to see a proof of concept and will need a little more convincing than just a computer generated model, especially if you’re trying to win funding from them.

Allows Greater Feedback

Having a physical model means you can easily take your product out to customers or clients and ask for much more detailed feedback.

Going through multiple iterations of the prototype means that you can keep on improving upon the design as you go, ultimately resulting in a much more polished final product.

You may find after prototyping that your customers have a client have a need that the product doesn’t address, but addressing the issue at this stage of the process is far easier than after having started full production.

Cheaper

3D printing is such an easy process that it removes the need to spend extra time and money on developing things such as moulds, patterns and tools.

The cost in 3D printing lies mainly with the machinery itself, rather than the materials, so after an initial outlay it should be more cost effective in the long term.

3D printing also produces less waste than traditional prototyping methods.

Useful for Testing

Thoroughly testing the product at this stage of the design may help identify any faults which could have had a major impact on production further down the line.

Many problems will often arise which just couldn’t have been identified from a computer model, and solving them at this stage in the process could save you a lot of money and time further down the line if you potentially have to recall and change a product.

Any changes that do need to be made can be made easily on a computer rather than requiring any special tools or processes.

The importance of prototyping in the design process cannot be overstated, and as the technology becomes more widely available we’re likely to see more and more companies taking advantage of its cost effectiveness.