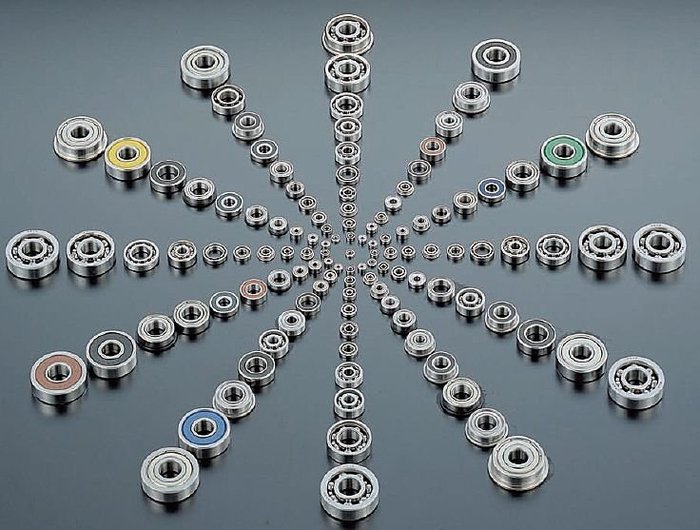

A miniature bearing is simply a bearing that has its outer diameter less than an inch or 25 millimeters. These are also called instrument bearing because of their wide application in designing instruments.

There are different kinds of miniature bearings with each available in various material options. The ones that are made from stainless steel are perfect for designing medical and dental equipment. A good miniature bearing supplier will give you all the information you need to select the right bearing for your design.

Technical features of miniature bearings:

- Efficiently minimizes the friction between the two surfaces

- Are very small is size and light in weight, and hence can fit in a small space.

- Can work in moderate to high-speed range

- They are always sealed with rubber or metal seals which protect them from contamination

- Since they are made from stainless steel or chrome alloy steel, they provide very high corrosion resistance and maximum fatigue life

- Materials are heat-treated which gives the bearing optimum dimensional stability

Miniature bearing selection criteria:

In order to ensure optimal speed and load carrying capacity from the bearing, it is important to choose the bearing very carefully. One must consider various factors before selecting the bearing. These factors include the right selection of bearing design, ring material, seals, cage, radial play, lubricant, ABEC grade and vibration levels.

Handling and mounting of miniature bearing:

Miniature bearing must be handled with care. Although sealing is provided, even small amount of contaminant can damage the metal balls of these bearings. Contaminants like dust, dirt or cotton fibers can come in contact with the critical surfaces of the bearing and damage them.

Extra care should be taken while mounting a miniature bearing. Upon using the incorrect method of mounting, brinelling can occur. Brinelling (small and permanent dents on the critical surface) as small as 0.1 microns, can have adverse effect on the performance of the bearing.

This will also decrease the life of the bearing significantly. Always press that ring of the bearing which is nearer to the mounting part i.e. press the inner ring if you are mounting it over the shaft, and the outer ring if you are mounting it into a housing.

Since the metal balls in these bearings are very small in size, care must be taken to ensure the load is radial only and there’s no misalignment. Even a small amount of misalignment (around ¼ of a degree) can make the ball to track in a non-circumferential path which will result in early bearing failure. The amount of radial play and track curvature value must be considered to determine the allowable misalignment in the bearing.

Interference fit must be provided so that there is no slippage between the surfaces and the bearing maintains its position rigidly.

Application of Miniature Bearing:

There are many applications of a miniature bearing. Apart from medical and dental equipment, these are used in various automation industries where achieving compactness is very essential. Miniature bearings are also found in clocks, watches, musical instruments, etc.

There are many companies that manufacture miniature bearings. One must put quality above costs while buying them. Always buy the bearing from a company that has many years of experience in manufacturing miniature bearings.

JSB Great Bearings, a bearing manufacturing company, is known for providing high-quality miniature bearings to its customers.