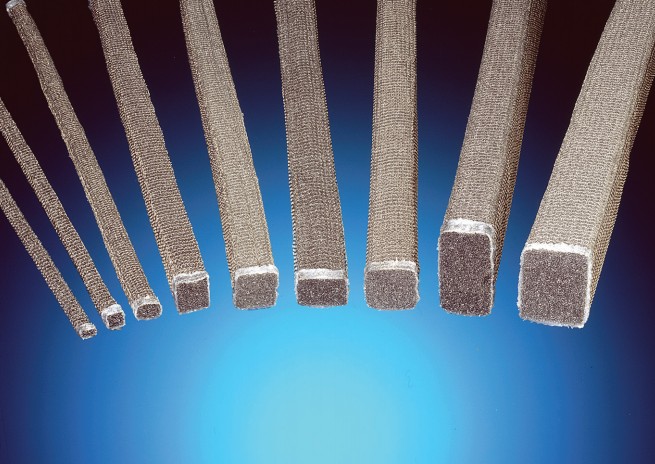

There are many different types of fabric shielding gaskets available in the market. But the fabric-over-foam shielding varieties have proven especially effective at shielding electronic equipment from the harmful effects of electromagnetic interference (EMI). Normally composed of fiber cloth such as synthetic polyester or nylon yarn covered with copper and nickel, fabric-over-foam shielding gaskets are in high demand among electrical engineers and designers. These materials owe their popularity to their conductive properties as well as their resistance to abrasion. While the foam core of these gaskets is made of polyurethane and is easily configurable, the combination of copper and nickel has a considerable impact on EMI, limiting its disruptive effects on other electronic equipment. An efficient design combined with the low cost of materials has made fabric-over-foam models the preferred gasket across numerous industries.

What Makes the Design Specifications of Fabric-over-foam Shielding Gaskets So Special?

The structure of fabric-over-foam gaskets is unique. They feature a cellular design that allows them to be slid easily through the spaces for a hassle-free installation. However, bear in mind that EMI shielding manufacturers can tweak the design to create products that fit your specific shielding requirements.

Importance of Shape

Gaskets are available in various shapes, and at first glance, they might seem random. But the truth is, quality gaskets are available only in D, L, P, and U-shapes. These shapes play an instrumental role in eradicating unwanted radiations, thereby preserving the functionality and efficiency of costly electronic devices and appliances. If a particular shielding design fails to meet your product’s shielding needs, you can always opt for a different shape and thickness. Depending on their material and shape, the compression of gaskets may range between 30 and 75 percent, leading to material system tolerance. A reliable supplier will create custom sizes and shapes with pressure-sensitive adhesives to meet certain application requirements.

Where Do You Use Them?

The benefits and features of fabric-over-foam shielding gaskets make them useful in applications with less compression force across the telecom, consumer electronics, military, automobile, and other industries. Plus, the material being lightweight, abrasion resistant, and easily customizable, the shielding products perform reliably and effectively. Some of the applications where fabric-over-foam shielding gaskets perform admirably include hard drives (both internal and external), panel gaskets, printers, telecom enclosure cabinets, cabinet doors, computer servers, card cage gaskets, IO gaskets and connector, and digital cameras.

Advantages of Using Fabric-over-foam Shielding Gaskets

EMI attenuation isn’t the only benefit that fabric-over-foam gaskets offer. Thanks to the presence of nickel and copper in the fiber material, these gaskets provide EMI shielding performance between 65 dB and 80 dB, greater durability, and low resistance for improved conductivity. They can easily be molded into a plethora of shapes as per your requirements and manufactured using the selected host materials. As a result, you enjoy optimized performance along with easy installation and low compression. Perhaps the most impressive feature is how the shielding performance of fabric-over-foam gaskets remains consistent, even when the temperature swings between minus 40 degrees Fahrenheit and 158 degrees Fahrenheit. The fact that these components cause the environment no harm is an added bonus.

Usability

Even though fabric-over-foam shielding gaskets have plenty of benefits, optimal performance can be achieved only in a controlled environment. If a specific device does not have an optimal temperature for proper operations, you should create a controlled surrounding before using the fabric-over-foam gasket, so your equipment remains unharmed by interference.

Choose a good quality fabric-over-foam shielding gaskets to guarantee the best EMI protection for your electrical equipment. Their inherent properties and features make them a fine addition to the end product. However, considering the variety of gaskets available in the market, you should make an informed decision while selecting the component.