When you have finally decided to replace the controlling system and you are moving on to the latest PLCs available in the market, you need to consider few things first before buying a brand new PLC. It is not that time when you will only find 1 type of PLC in the market. It is 2015, and first Programmable logic controller was made in 1969. You do the math. Now things have changed and we have also seen so very elegant safety certified PLCs. You need to set your requirements straight. What you need and what you will get from changing or replacing the existing controllers.

A Little Knowledge

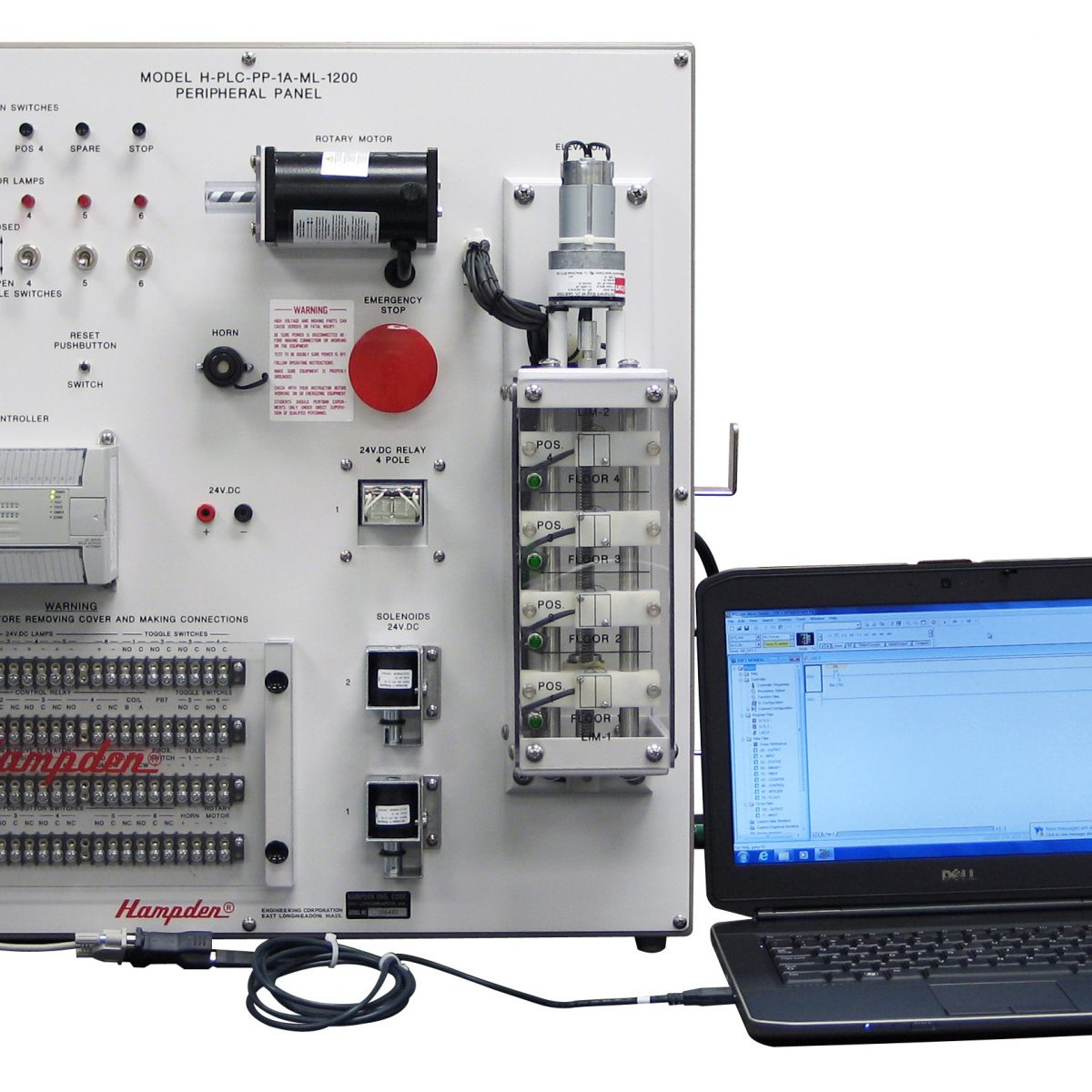

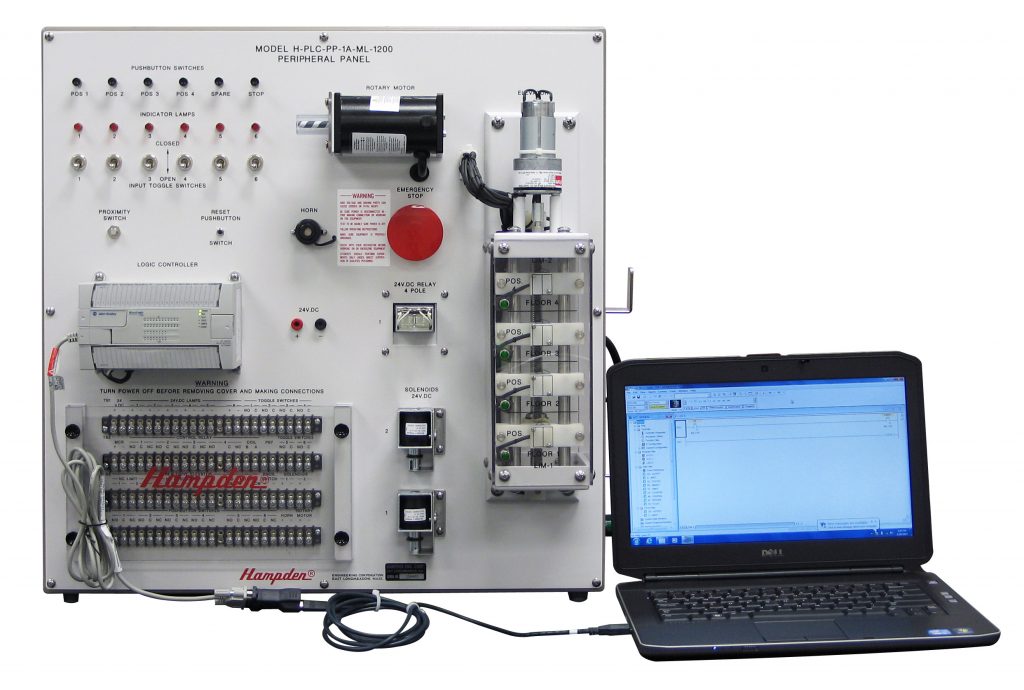

I assume that you are not using the old fashioned hardwired relays. If you are then you just have to move to these programmable logic controllers and save your time and money. How you can save your time and money? How you can get maximum production by using the PLCs. Well, when you will move to the PLCs, you will get rid of all the stressed situations. It will easy to monitor and eliminate the fault by using PLC. It will save all the engineering costs that you once bear all the time. When it will save the time, it will result in the giving you maximum working hours and maximum production, which will ultimately result in maximum profits. Here are the things that you should consider before choosing the right PLC for your industry.

- First you will evaluate that the power which you will supply to the PLC is DC or AC. It depends, they are different classes of PLC nowadays and when you are sure of the power supplies then you can make a better decision.

- You have to make sure that the PLC you are buying has enough memory to run the user programs. If the PLC does not have that much memory, then you are wasting the money. Make sure you are buying the right one with right amount of memory to execute your programs.

- Then you have to consider the speed. Make sure that the system runs fast enough to complete your applications.

- Then you will have to come to the software. What type of software will be used to program the PLC?

- Make sure that the PLC can manage the number of inputs and outputs that your application requires. When you are investing serious money, then make sure you are buying a right product that will fulfil your requirements.