Copper Oxide is one natural resource which is easily found in abundance. Obtained by the oxidation of Cu, CuO (Copper Oxide) has attracted the attention of the scientists due to its easy availability, cheap price and its excellent optical, electrical, physical and magnetic properties. It is extensively used in varied applications such as catalysis, gas sensor, solar energy conversion and in the field of emission. These novel properties can be obtained by synthesis in Copper Oxide Nanoparticles which shows excellent performance compared to other bulk counterpart. CuO nanofluids acts as a coolant in refrigerators when nanofluids is mixed with carrier fluid to enhance the energy transfer.

Preparation of Copper Oxide Nanoparticles

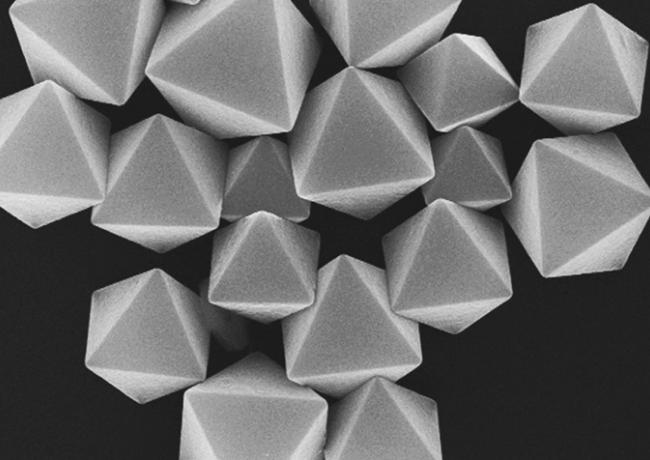

By investing great efforts, the scientists and researchers found many methods conducive to produce well dispersed nanoparticles with varying shapes, sizes and morphology through thermal oxidation, electrodeposition, hydrothermal treatment, high-temperature combustion, gas-phase oxidation, quick-precipitation etc. Hydrothermal and quick-precipitation are widely used for the preparation because they involve safe and environment friendly synthesis methods at moderate temperatures and quick-precipitation is more attractive due to simple operation, ease of mass production and cost-effectiveness. The sol-gel method is conveniently used because it is easy and economical.

In this method, a colloidal suspension (sol) and gelation of the sol are formed to create a flowing liquid phase. Nanocrystalline and bulk CuO are prepared by thermal decomposition of fresh preparation of Cu(OH)2 at different temperatures. Cu(OH)2 is prepared by reacting with aqueous solution of copper nitrate and sodium hydroxide. Sodium hydroxide is added drop by drop till the PH of solution reaches to 12 and the chemical reaction takes place. The resultant is bluish green liquid which is washed with distilled water till they are free from nitrate ions. The residual precipitate is further heated on 100 degrees for 10 hours. Copper hydroxide decomposes into copper oxide upon heating. Following this process, bulk and nanocrystalline CuO samples are formed by heating copper hydroxide in air for three hours at different temperatures.

Characterization of Copper Oxide Nanoparticles

X-ray diffractometer, differential thermal analyser (DTA), thermogravimetric analyser (TGA) and vibrating sample magnetometer are used for characterization of CuO nanoparticles.

Adopting DTA method, the sample and the inert reference material are heated under identical conditions. The difference of temperature of sample and reference material is continuously recorded during the procedure. The difference in temperature is plotted against the temperature. Changes in the sample is detected due to the absorption or evolution of heat. The DTA method helps to detect transition in temperature, heat capacity, identification of materials etc. An endothermic and exothermic transition gives rise to a peak in the DTA curve. Adopting TGA process, the thermal stability and fraction of volatile components in a material by observing the weight change that occurs during the heating of the material. The measurement is carried out in air or in an inert atmosphere and the weight is recorded as a function of increasing temperature. To stable the condition of the sample, maximum temperature is selected to stabilize the condition of the sample at the end of the experiment.

Conclusion

Copper Oxide Nanoparticles has attracted the attention of researchers and scientists due to its diverse applications. It can be used as doping material in semiconductors, chemical sensors, biological applications, efficient antimicrobial agents etc. An extensive research is being conducted on finding out its varied uses and compatibility.